The Three Pillars of NomoFlow™ Technology

More Than Features: The Foundational Principles of Reliability

The NomoFlow™ platform's value isn't derived from a list of features, but from three interconnected engineering pillars. These principles work in concert to systematically eliminate the variability and uncertainty—the 'Black Box Risk'—inherent in conventional manufacturing. This is how we build verifiable reliability into every product, from the first micron of material.

Pillar 1

Unmatched Consistency

Systematically eliminating batch-to-batch variation, the primary source of diagnostic uncertainty.

Our AI-driven predictive quality control system monitors over 500 parameters in real-time. Instead of merely inspecting for failure post-production, NomoFlow™ anticipates and corrects micro-deviations before they impact performance. This closed-feedback loop transforms manufacturing from a game of chance to a predictable science, achieving a coefficient of variation (CV%) under 3%—a level of consistency that directly translates to reliable clinical outcomes.

The Evidence

Verifiable Stability

This chart compares the batch-to-batch CV% of products manufactured on NomoFlow™ versus conventional methods. Note the tight, predictable grouping of reOpenTest results, demonstrating a process under complete control, contrasted with the wide, unreliable scatter of a typical competitor.

Pillar 2

Superior Sensitivity

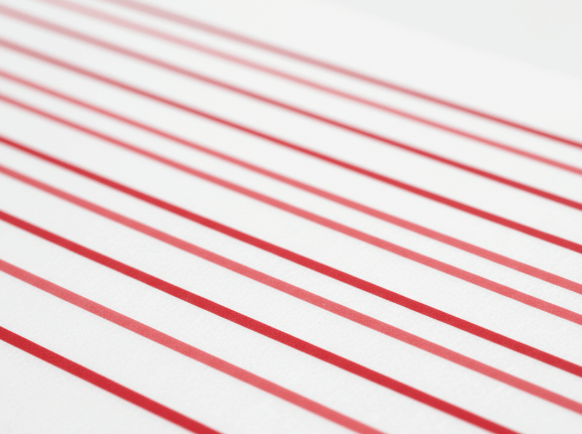

Engineering the membrane for maximum signal-to-noise ratio, ensuring detection at critical low concentrations.

Sensitivity is a function of design. NomoFlow's™ precision deposition technology dispenses reagents in a uniform, non-overlapping monolayer. This maximizes the effective surface area for analyte binding, creating a superior signal-to-noise ratio. Unlike traditional 'spray' methods that result in reagent piling and inconsistent gaps, our process ensures every test line has the optimal architecture to capture even the lowest concentrations of target analytes, minimizing the risk of false negatives.

The Evidence

Uniformity by Design

This visualization contrasts NomoFlow's™ uniform reagent line (left) with a competitor's inconsistent line (right). The even distribution maximizes binding sites for a strong, clear signal, while the competitor's clumps and gaps lead to weak and unreliable results.

Pillar 3

Precision Engineering

Micron-level control over every variable, guaranteeing performance is designed in, not inspected on.

The foundation of our consistency and sensitivity is pure mechanical precision. Our robotic substrate handling, coupled with deposition nozzles controlled at the micron level, ensures that every square millimeter of a `reOpenTest CORE™` uncut sheet is identical. We have engineered out the human and environmental variables that plague traditional manufacturing. Performance is not a goal we hope to achieve through quality checks; it is an inherent property of the materials we create.

The Evidence

The Physical Manifestation

This high-resolution macro photograph of a `reOpenTest CORE™` uncut sheet is the tangible proof of our process. Observe the flawless uniformity and precision of the test lines—a physical object that is the direct, inevitable result of our engineered approach.

From Proven Pillars to Tangible Value

These three pillars are the engine of reOpenTest's technical superiority. They are how we translate engineering principles into the verifiable reliability and performance that create tangible clinical and business advantages for our partners.

Explore Business Value